|

Ningbo Honghuan Geotextile Co.,LTD.

|

Gold Index: 8875

Reinforcing Polypropylene Fibers For Concrete , Crack Resistance

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Reinforcing Polypropylene Fibers For Concrete , Crack Resistance

<strong style="font-family:

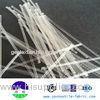

Reinforcing Polypropylene Fibers For Concrete , Crack Resistance

Description:

High-strength Polypropylene Fiber , manufactured from 100% virgin homopolymer polypropylene monofilament , is an easy to apply and finish ,fully oriented , fibrous reinforcement for concrete. This engineered fiber provides a mini-reinforcing system forming a more cohesive, inner supported mix that functions as a reinforcement intended to reduce plastic and hardened shrinkage cracks , handling stresses and also to improve impact strength, fatigue resistance and concrete toughness .Non-corrosive, chemically inert , and 100% Alkali proof.

Function:

Crack Resistance : It is the most effective fibers available for minimizing cracking throughout the life of the concrete. Compared to the competition, this fiber produces a excellent test result with a 70% improvement in crack reduction , when mixed (0.9Kg/m^3) in precast concrete.

Impact and shatter Resistance: It increases the amount of energy necessary for concrete to crack when a dynamic impact load is applied.

Freeze-Thaw Resistance: It is improved due to fiber’s ability to knit together the concrete in its plastic state.

Acid, alkali and UV Resistance :As made from virgin polypropylene ,the fiber is highly resistant to both alkali and acid environments.

Concrete Finishing : Due to the low denier material, it will leave the surface with the unsightly appearance that is often the case when longer, thicker fibers are used.

Application:

High strength fiber is mainly used with performance concrete applications such as industrial floors, bridge decks, shotcrete, loading docks, precast products – anywhere that steel reinforcement reduction or replacement is the objective.

Installation:

Recommended dosage rate of HP5-260 is 0.2% to 2.0% by volume of concrete added directly to the concrete mixing system during, or after, the batching of the other ingredients and mixed at the time and speed recommended by the mixer manufacturer (usually four to five minutes).

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

Ningbo Honghuan Geotextile Co.,LTD. [China (Mainland)]

Business Type:Manufacturer

City: Ningbo

Province/State: Zhejiang

Country/Region: China (Mainland)

.jpg)

.jpg)

.jpg)